Image 1 of 4

Image 1 of 4

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

Image 4 of 4

Image 4 of 4

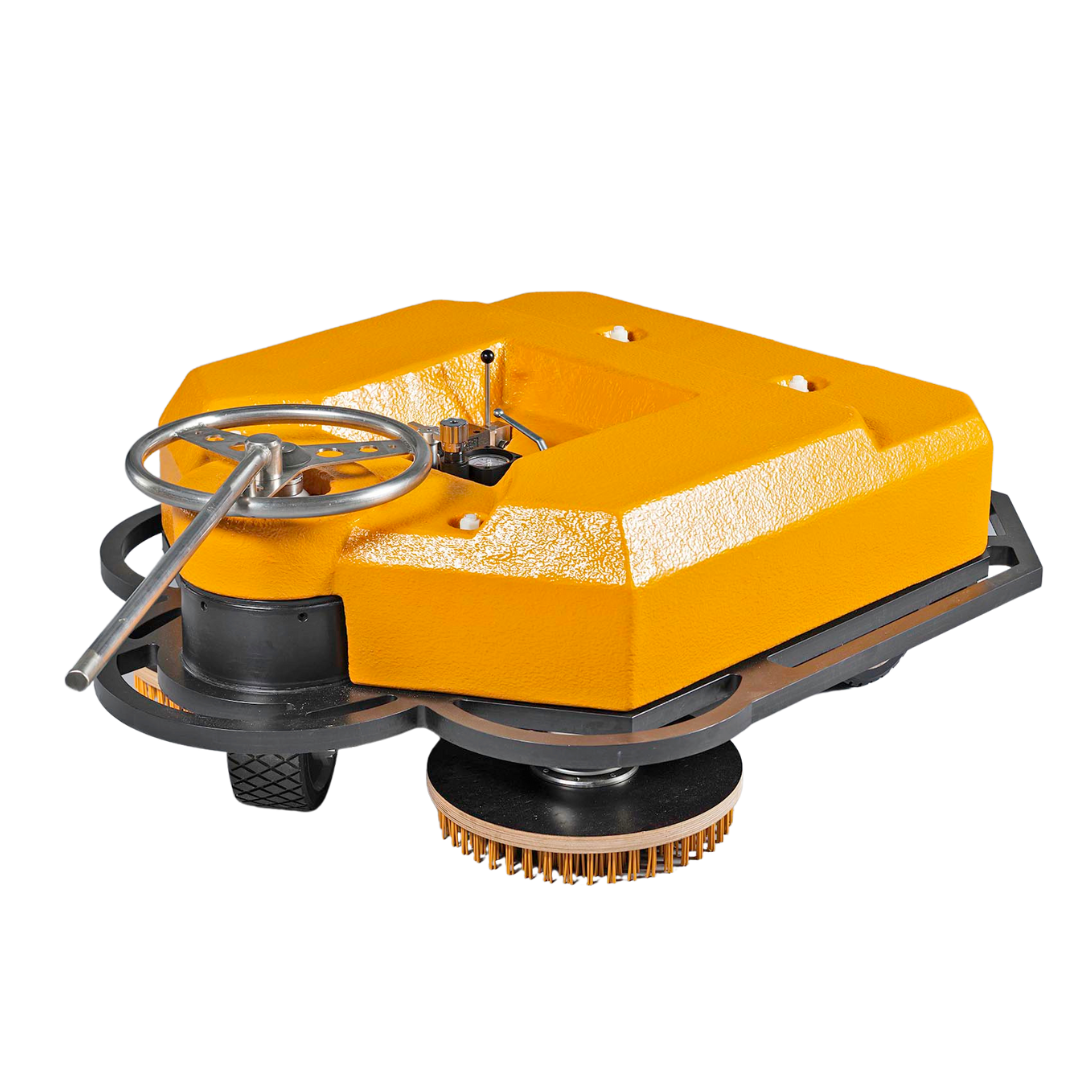

Subsea MC212 Underwater Twin Cleaning Unit

The most efficient underwater cleaning unit available

Our MC212 underwater cleaning unit has a track record of over 30 years of service. The twin tool unit consists of two halves connected by a hinged joint and is designed for cleaning light and heavy marine fouling from offshore oil and gas platforms, jetties, piles, windmills and other curved structures as well as medium-sized ships.

The MC212 was, for instance, used to clean jetty piles in the harbor of Terneuzen, Holland. The jetty piles were cleaned from the waterline down to 10 meters below the surface. Very heavy marine growth over 40 cm thick and consisting of oysters was removed. The removal of these very thick layers of marine fouling proved to be no problem at all for this cleaning unit.

Besides being ideal to clean curved surfaces, the MC212 is also a very good choice when cleaning medium-sized ships fast and efficiently. The unit combines the maneuverability and flexibility of our smaller machines with a cleaning rate closer to our largest unit.

The most efficient underwater cleaning unit available

Our MC212 underwater cleaning unit has a track record of over 30 years of service. The twin tool unit consists of two halves connected by a hinged joint and is designed for cleaning light and heavy marine fouling from offshore oil and gas platforms, jetties, piles, windmills and other curved structures as well as medium-sized ships.

The MC212 was, for instance, used to clean jetty piles in the harbor of Terneuzen, Holland. The jetty piles were cleaned from the waterline down to 10 meters below the surface. Very heavy marine growth over 40 cm thick and consisting of oysters was removed. The removal of these very thick layers of marine fouling proved to be no problem at all for this cleaning unit.

Besides being ideal to clean curved surfaces, the MC212 is also a very good choice when cleaning medium-sized ships fast and efficiently. The unit combines the maneuverability and flexibility of our smaller machines with a cleaning rate closer to our largest unit.

The most efficient underwater cleaning unit available

Our MC212 underwater cleaning unit has a track record of over 30 years of service. The twin tool unit consists of two halves connected by a hinged joint and is designed for cleaning light and heavy marine fouling from offshore oil and gas platforms, jetties, piles, windmills and other curved structures as well as medium-sized ships.

The MC212 was, for instance, used to clean jetty piles in the harbor of Terneuzen, Holland. The jetty piles were cleaned from the waterline down to 10 meters below the surface. Very heavy marine growth over 40 cm thick and consisting of oysters was removed. The removal of these very thick layers of marine fouling proved to be no problem at all for this cleaning unit.

Besides being ideal to clean curved surfaces, the MC212 is also a very good choice when cleaning medium-sized ships fast and efficiently. The unit combines the maneuverability and flexibility of our smaller machines with a cleaning rate closer to our largest unit.

-

Dimensions:

Length: 450 mm

Width: 800 mm

Height: 250 mm

Weight in air: 23 kg

Weight in seawater: 1 kg buoyant

Cleaning rate: 450 m2/hour

Depth rating: 70 m

Hydraulic requirement:40ltr/min @ 140 bar